The recent wave of foreign investment attraction into Vietnam has led to the development of supporting industries.

Notably, with the trend of further integration, many domestic companies have invested in technology, equipment and human resources in order to engage further in the supply chains of multinational corporations in Vietnam.

There are large numbers of small and medium enterprises, but most of them are still weak in capital, human resources and management processes. Therefore, to achieve revolutions in this field, the role of leading enterprises is needed to connect and generate greater motivation.

Samsung Vietnam's billion-dollar projects are typical examples of leading companies assisting the development of supporting industry enterprises.

Localization rate in many fields is still low

According to the Ministry of Industry and Trade, in 2018, the number of enterprises working in the supporting industry was about 2,000 in producing spare parts and components and more than 1,500 enterprises producing materials for the textile and footwear industry, accounting for nearly 4.5% of the total number of enterprises in the manufacturing industry.

Supporting enterprises have created jobs for more than 600,000 employees, equivalent to 8% of the manufacturing industry, with about VND 900,000 billion in net revenue in 2018, accounting for about 11% of total revenue in the manufacturing industry.

Remarkably, some Vietnamese components manufacturing enterprises have quite good capcities in some fields such as manufacturing patterns, bicycle and motorbikes parts, standard mechanical components, power cables, plastic components, technical rubber and tires.

These products have met the domestic demand and have also been exported to other countries around the world. Domestic supporting industry enterprises are also more and more proactive in applying standards and modern management tools in production and manufacturing.

In addition, the capacity of producing domestic supporting industry products has gradually improved. Specifically, in November 2018, the export turnover of supporting industry products, including car components, electronic parts, textile and footwear materials reached USD 35 billion, increasing 16% compared with the same period the previous year.

Particularly in 2018, one of the very noticeable events was a leading Vietnamese enterprise implementomg a car manufacturing project with not only fast but also well-planned steps.

However, in general, the supporting industry in Vietnam has not met the practical requirements.

An evaluation by the Ministry of Industry and Trade shows that the current scale and capacity of Vietnamese supporting industry enterprises still has many limits: small numbers of companies, lack of resources and technology to improve productivity, and below – demand human resources.

Domestic supporting industry products are mainly simple components with uncomplicated details, with medium and low technology content and small value in the product value structure.

Meanwhile, the gap between the requirements of multinational corporations and the capacity of domestic manufacturing enterprises is still huge. A number of Vietnamese enterprises have participated in the supply of supporting industry products, but very few have long-term development strategies to make further investments in equipment, technology, management or human resources.

For instance, in the automobile sector, the localization rate of individual cars under 9 seats is low, about 7-10% on average, while more than 80% of components and automobile parts are still provided by the parent companies or transnational corporations from overseas, and making a car needs from 30,000 to 40,000 components.

As for the electronics industry, the localization rate of household electronics is about 30-40%, while that of the automobile industry is over 40%, mainly recorded in motorbike production.

Le Duong Quang, President of the Vietnam Supporting Industry Association, said that Vietnam's supporting industry enterprises are currently facing barriers in capital access, technology innovation and product output issues. Moreover, a weakness of the supporting industry enterprise is that it is disjointedand disconnected.

"Apart from having to actively access support policies, enterprises must be more enthusiastic in expanding connections and coordinating with each other for mutual development", Quang said.

At a conference on solutions to promote the development of Vietnam's supporting industry held in December 2018, Prime Minister Nguyen Xuan Phuc emphasized that we need to learn from Japanese and South Korean people in terms of how to develop the supporting industry so that by 2030, there will be around 2,000 qualified enterprises supplying supporting industry products for assembly enterprises and multinational corporations in Vietnam.

“The world is changing every day and every hour on how we manufacture and build a brand for our products. It is no longer the case that only one enterprise can produce a single product, but a product is produced by a number of businesses relying on the strengths of each enterprise to enhance the competitiveness of the product, of the country," the Prime Minister said on the situation.

Qualitative change

At present, the supporting industry is an area prioritized by the Vietnamese Government. In 2011, the Prime Minister issued Decision No. 12/2011 / QD-TTg on policies to develop a number of supporting industry fields and Decision No. 1483 / QD-TTg dated August 26, 2011, with a list of supporting industry products that are prioritized.

In addition, the 2014 Investment Law and Decree No. 118/2015 / ND-CP defined a number of articles of the Investment Law. Accordingly, the production of supporting industry products is a field that receives special investment incentives in Vietnam. In 2017, the Government enforced the Supporting Industry Development Program to 2025 in order to support businesses in this field.

However, facts show the development of the supporting industry in Vietnam needs a great deal of investment and support from the Government, andy the determination of enterprises to produce and develop business strategies.

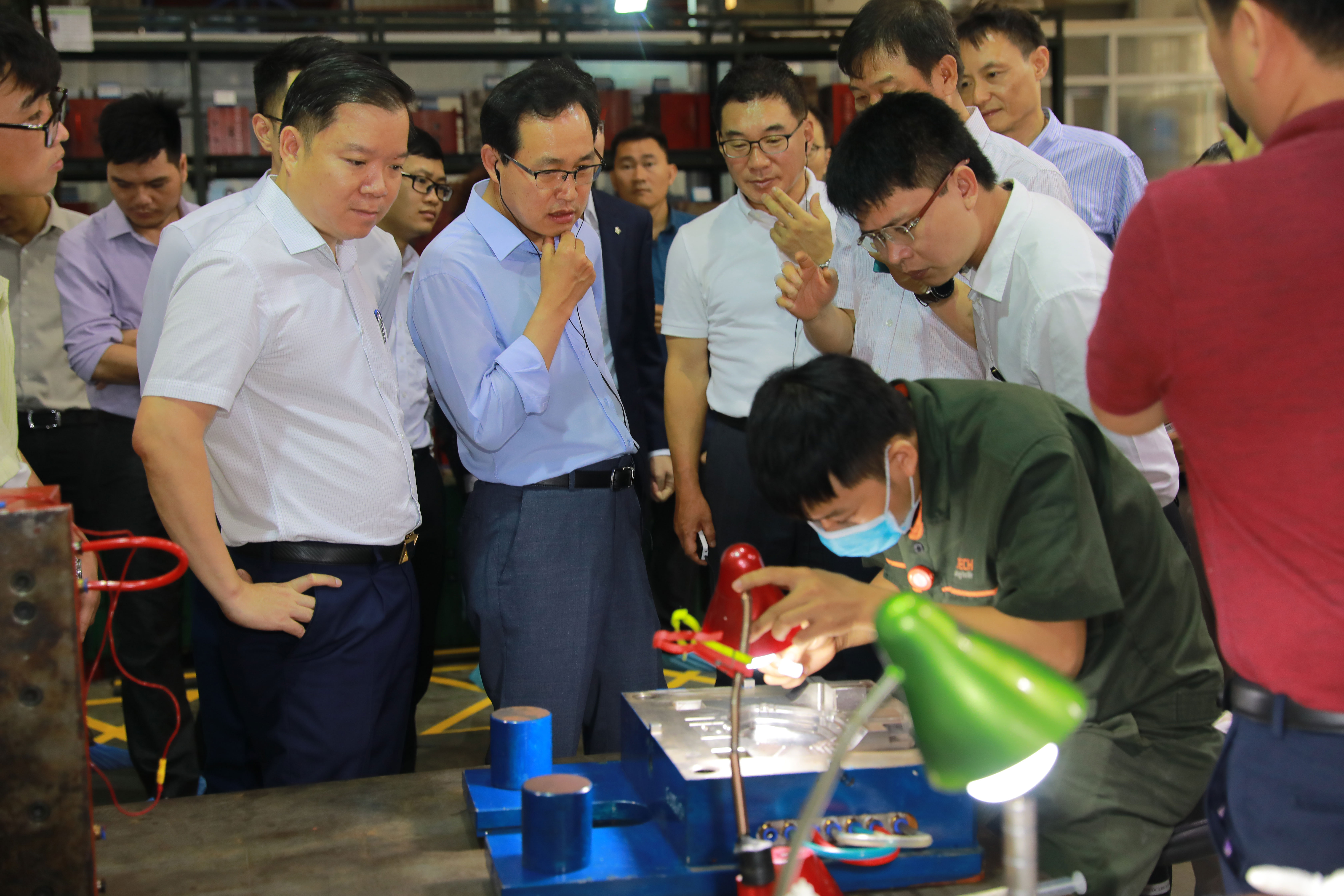

As a Tier-2 vendor of plastic components to Samsung (the world's leading mobile phone manufacturer investing in Vietnam), Man Chi Trung, General Director of An Trung Industries, shared the difficulties of supplying other companies, but for Samsung it is even more challenging as this is global giant with extremely high requirement for product quality.

Therefore, in order to join the supply chain, the parent company of An Phat Holdings (APH) which owns An Trung Industries, had to strive 200% to be able to meet all the requirements.

According to the contract, An Trung Industries will officially supply components for Elentec starting from March 2019. These components will be used directly for the production of Samsung phones, contributing to bringing quality "Made in Vietnam" products to global customers.

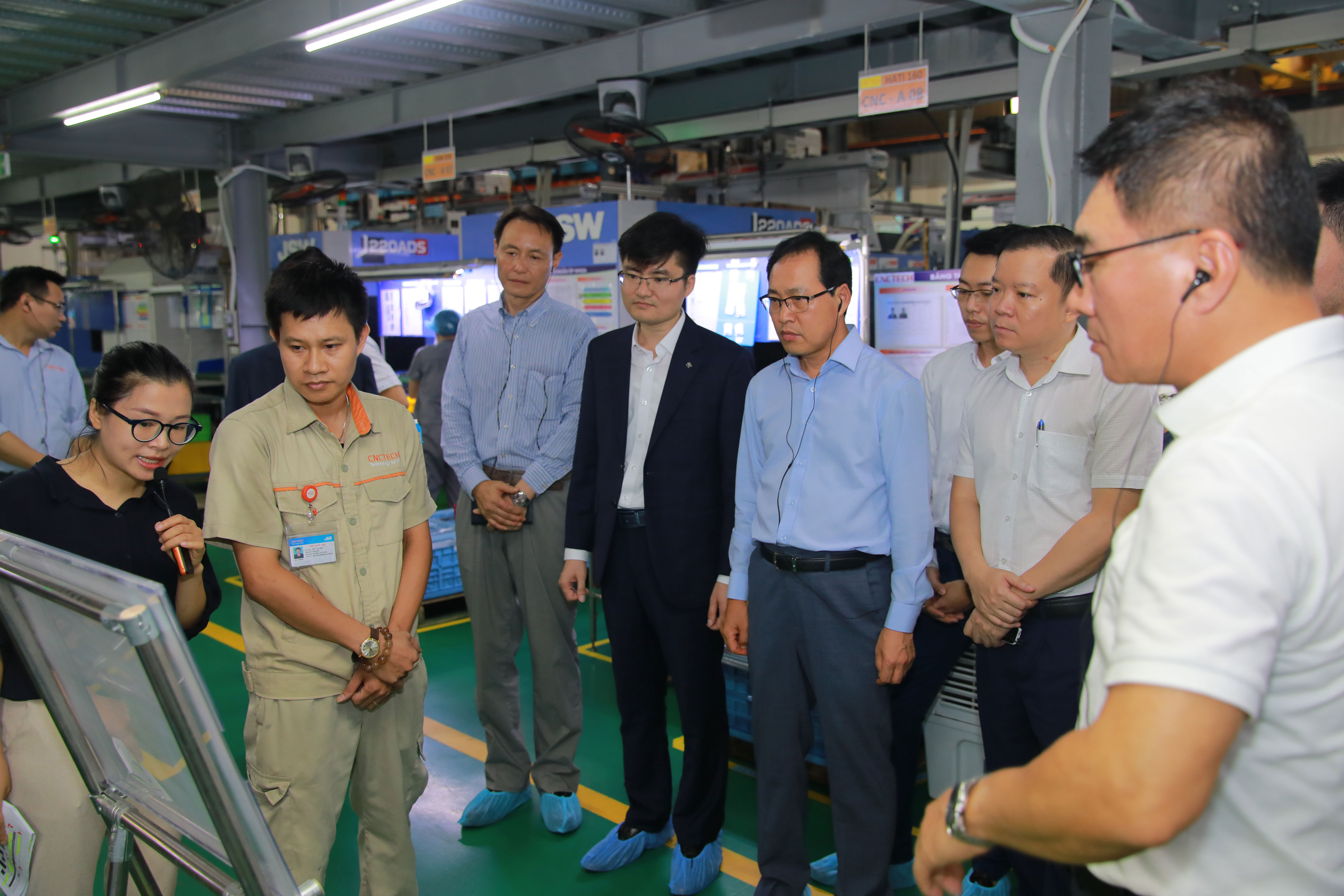

In order to do this, besides investing in technology, An Trung Industries also receives direct support from South Korean technical experts who have helped to supervise and share experiences in supplying partner -required products as as well as improving the production and management processes of enterprises in alignment with international standards.

“Elentec and Samsung’s supplier selection criteria are Quality - Price - Time. These are the three most important requirements. Once these are fulfilled, the hardships are removed”, Man added.

Recently published data shows that the localization rate of Samsung in Vietnam is 59% and the total number of Samsung vendors has reached 308 companies. In particular, the number of Vietnamese enterprises that are Tier-1 vendors has increased sharply from 4 in 2014 to 35 by the end of 2018 and is expected to reach 50 by 2020.

Additionally, the number of Tier-2 vendors also increased from 157 businesses in 2018 to 170 businesses in 2019.

However, in order to become a Samsung supplier, all businesses, including foreign and Vietnamese enterprises, must actively prove their capacity and determination to participate in Samsung global’s value chain.

Samsung commits to create equal opportunities with no difference for foreign and Vietnamese businesses when participating in the global supply chain, and always strives to help Vietnamese businesses to exploit their potential through training programs for 200 Vietnamese consultants.

Mr. Ngo Khai Hoan, Deputy Director of Industry Department (Ministry of Industry and Trade), said the collaborative project to train 200 Vietnamese consultants in 2018-2019 between the Ministry of Industry and Trade and Samsung is a remarkable way to create innovation for businesses participating in the global supply chain.

After this program, many businesses have gained positive results, helping to increase their productivity and saving billions of Vietnam Dong.

Typically, Rang Dong Plastic and Long An Plastic Joint Stock Company has made 62 improvements, especially reduced rolling machine replacement time from 105 minutes to 48 minutes; and reduced packaging and cutting stage from 165 m / shift to 50 m / shift.

SAMETEL Joint Stock Company has made 86 improvement, thereby increasing productivity from 62% to 95%, reducing wasteful operations by repositioning supplies, on average from 42 seconds / product to 13.5 seconds / product.

Mr. Le Hong Sinh, General Director of Viet Filter Production Joint Stock Company, one of the enterprises participating in the Vietnamese consultants training program, said their company has been searching for solutions to improve productivity and quality but cannot implement them due to lack of experience.

"After being guided by the consultants and figuring out our limitations, the company has implemented numerous improvements to enhance labor productivity, reduce inventories, and improve the working environment", Sinh said.

Talking about this cooperation project, according to Mr. Choi Joo Ho, President of Samsung Vietnam, the success of the consultant training program from 2018 is valuable recognition of Samsung efforts on the journey to join hands with the Vietnamese Government to improve the competitiveness of enterprises.

“This is also a motivation for us to continue promoting and making appropriate adjustments to bring more efficiency to the program in 2019. Samsung Vietnam always commits to be one of the “leaders” to develop Vietnam's supporting industry.”

After training courses in Vietnam, 30% of the best attendees will be sent to South Korea for intensive courses.

From practical experience gained on the course, Ms. Nguyen Thi Xuan Hoa (university lecturer), one of those to have completed intensive training in South Korea, said it is a very methodical and practical course that holds real value for Vietnamese consultants and enterprises.

“Under the training of Samsung experts, attendees are trained to think in a quantitative way in production, optimal methods in quality management, quality cost management, information management in production and non-stop improvements that can be be effectively applied in reality”, Hoa said.

The training program for 200 Vietnamese experts in the supporting industry ended in October. However, as soon as this program was three quarters of the way through, the Ministry of Industry and Trade built a plan to use the post-training human resources effectively. From July 2019 to November 2019, 52 Vietnamese enterprises will join a business improvement consultancy program with Vietnamese experts who have just completed the training course. In addition, Samsung will continue to send South Korean experts and interpreters to accompany the Ministry of Industry and Trade to implement this plan.

Since its investment started in Vietnam, Samsung manufactories have been constantly growing, making a great contribution to the state budget, creating a great number of jobs for locals and accounting for a high percentage of Vietnam’s total export turnover./.